The increasing demand for sustainable agricultural practices has led to the exploration of Granular organic fertilizer production lines. In Utah, where agriculture plays a vital role in the economy, establishing such production facilities can significantly enhance soil health and crop yield. This article aims to discuss the intricacies involved in setting up a Granular organic fertilizer production line within this unique geographical context.

Understanding Granular Organic Fertilizer Production Lines

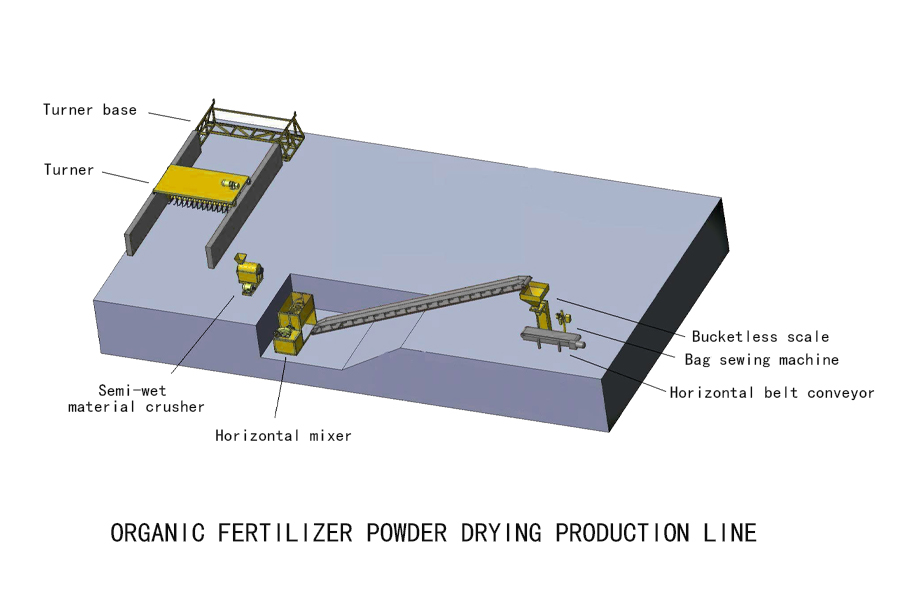

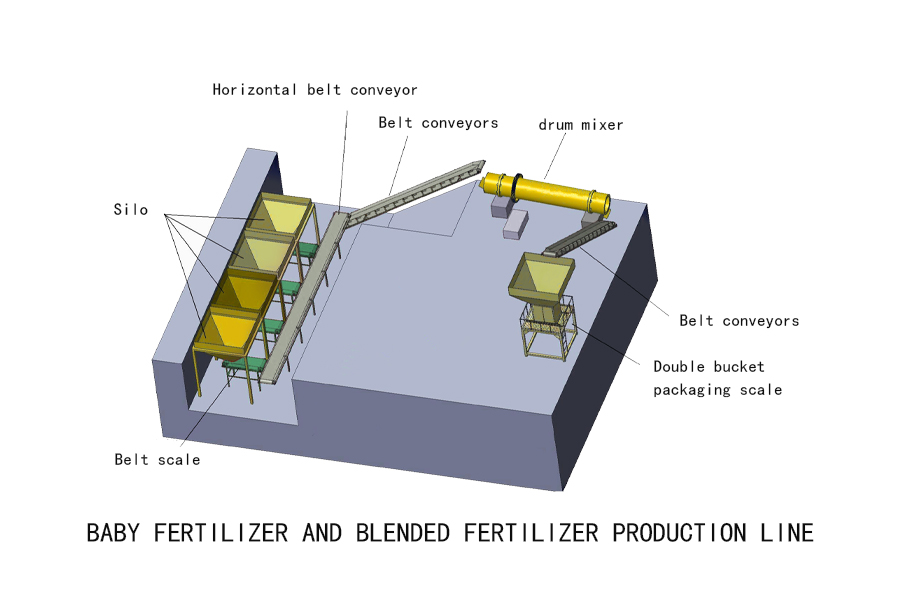

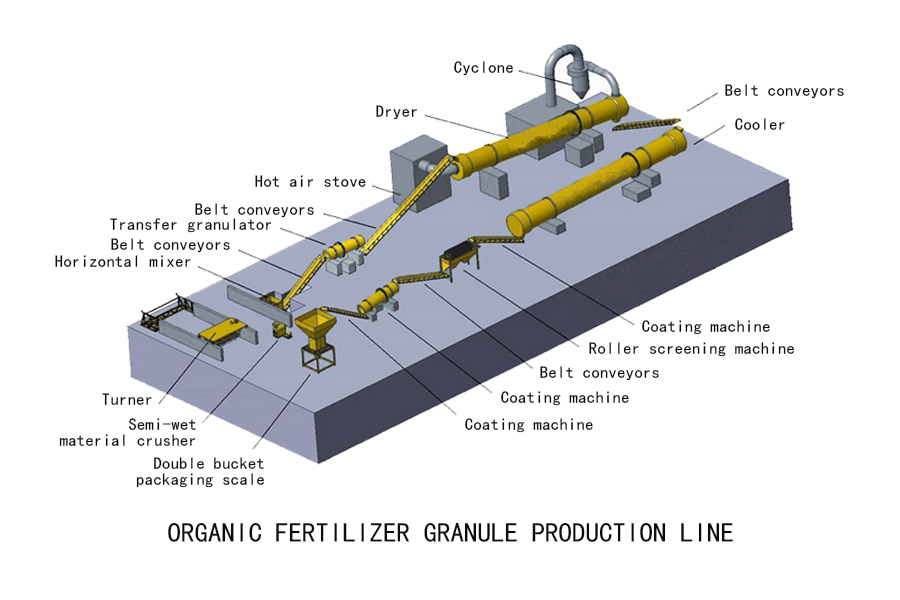

A granular organic fertilizer production line is designed to convert raw organic materials into nutrient-rich granules suitable for agricultural use. The process typically involves several stages, including composting, grinding, mixing, granulating, and packaging. Each stage requires careful monitoring and control to ensure that the final product meets quality standards essential for effective fertilization. By implementing advanced technologies and methodologies in these processes, we can optimize efficiency while minimizing environmental impact.

Find more about fertiliztion machine.

Exploring Fertilization Machines Used in Production

The success of any granular organic fertilizer production line heavily relies on specialized fertilization machines that facilitate various stages of processing. These machines include compost turners for aerating raw materials, grinders for particle size reduction, mixers for uniform blending of ingredients, and pelletizers or granulators that shape the mixture into granules. Additionally, screening equipment ensures that only high-quality products reach consumers by removing oversized particles or impurities from the final output.

Xincheng’s Role in Enhancing Fertilizer Production

Xincheng has emerged as a key player in providing innovative solutions tailored specifically for granular organic fertilizer manufacturing processes. Their state-of-the-art machinery not only enhances productivity but also incorporates eco-friendly practices aimed at reducing waste during production. Furthermore, Xincheng offers comprehensive support services ranging from installation to maintenance training which are crucial for optimizing operational efficiency over time.

Conclusion: Advancing Sustainable Agriculture through Granular Organic Fertilizer Production Lines

The establishment of a granular organic fertilizer production line represents an important step towards promoting sustainable agriculture practices within Utah’s diverse farming landscape. By leveraging advanced technology and collaborating with industry leaders like Xincheng, we can create high-quality fertilizers that contribute positively to soil health while supporting local economies. Ultimately, investing in such initiatives will pave the way toward more resilient agricultural systems capable of meeting future food demands sustainably.