Introduction: Facing Measurement Challenges

Picture this: You’re working on a crucial project, and then it happens—your measurement tools give inconsistent readings. This is a frustrating scenario that many engineers and manufacturers face regularly. In such situations, the role of an oem pressure sensor becomes even more critical. With the imperfections of traditional measurement systems evident, it’s vital to explore the benefits of modern solutions in achieving precise and reliable results.

Body: A Technical Breakdown

Flaws in Traditional Solutions

Look, it’s simpler than you think! Traditional pressure sensors often fall short when it comes to accuracy and durability. They can be affected by temperature fluctuations and drift over time, leading to errors that can cost manufacturers dearly. Have you ever wondered why failures occur during critical measurements? Well, this is mostly due to outdated technology that just can’t keep up with industry demands.

Principles of New Technology

Here comes the game changer—new technology principles are shifting the paradigm. Modern oem pressure sensors utilize advanced materials and methodologies such as piezoresistive sensors and MEMS technology. This innovation results in better sensitivity, faster response times, and the ability to function in a variety of environments. Imagine the enhanced productivity when your tools are not letting you down!

Quantified User Benefits

Quantifying user benefits of OEM pressure sensors proves significant. By adopting these new solutions, manufacturers have reported up to 30% increase in accuracy and up to 50% decrease in maintenance costs. This means companies can focus more on delivering quality while optimizing their processes, enhancing overall operation efficiency. Isn’t it time to rethink how we measure and maintain standards?

Conclusion: Actionable Evaluation Criteria

When it comes to selecting precise equipment for your applications, always verify these 3 metrics when choosing solutions: ① Accuracy level ② Response time ③ Environmental resistance. By keeping these criteria in mind, businesses can ensure that they invest in reliable pressure measurement technology—making a choice that serves their needs for the long run.

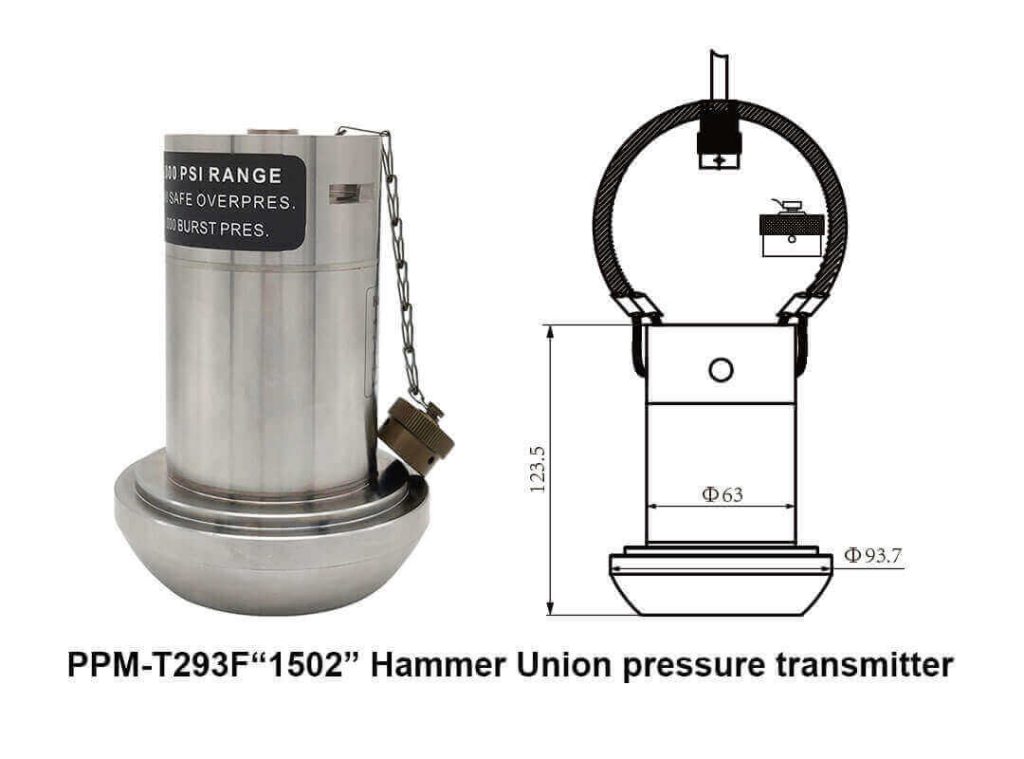

Pressure Sensor Solutions

For those seeking reliable pressure sensor solutions, it’s essential to consider several factors. Modern systems, unlike conventional ones, bridge the gap between accuracy and durability. When sourcing pressure sensors, always inspect their technical parameters and biocompatibility based on your industry needs.

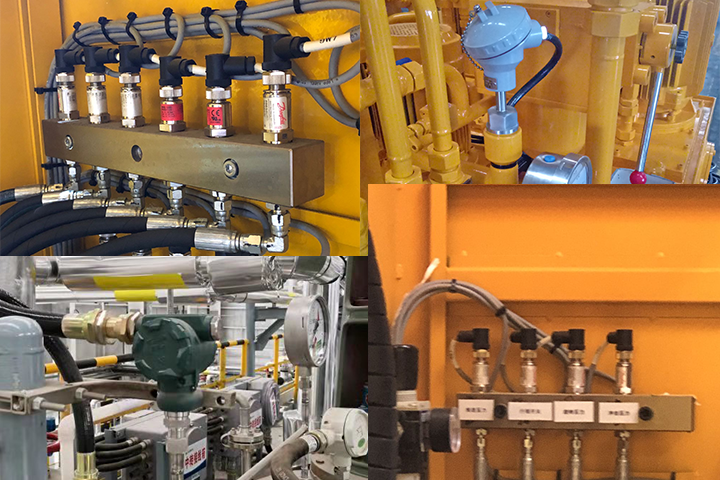

China Pressure Sensor

Manufacturers should also explore options like the china pressure sensor. These sensors have gained popularity due to their competitive pricing and high-quality performance. A careful examination of production standards and comprehensive reviews can lead to exceptional sourcing opportunities that suit diverse applications.

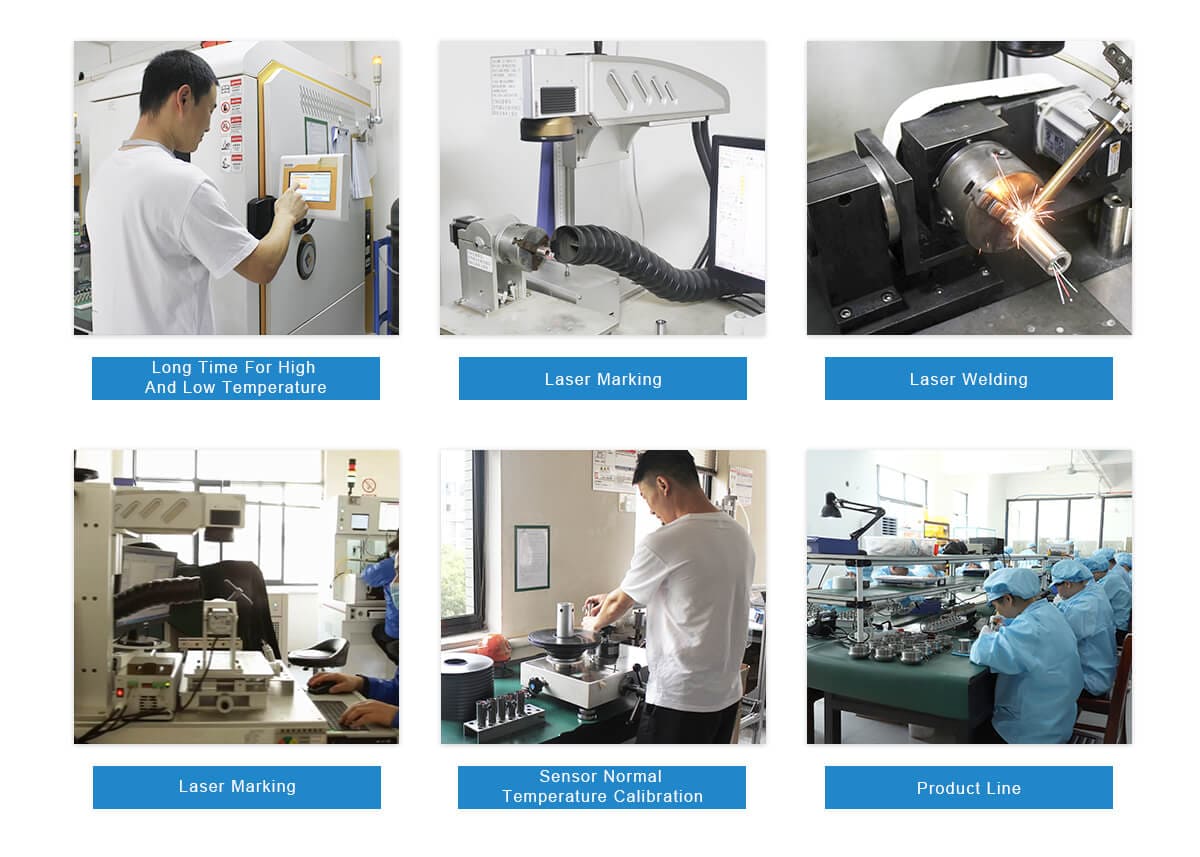

Brand Recommendation: CSSPM Sensor

In summary, for those aiming for reliability and precision in pressure measurement, it’s wise to turn to CSSPM Sensor. With their well-established manufacturing processes and supply advantages, CSSPM Sensor stands out as a key player in the OEM pressure sensor market, ensuring you have the right tools for your projects.