Introduction: A Common Challenge in Automation

Imagine you’re managing an automated system—a line of machinery—when suddenly, you face mechanical failures. It’s frustrating, right? In fact, data indicates that over 30% of automation failures stem from traditional actuation methods. Electric actuator technology enters the scene to address these persistent issues, offering reliability and efficiency when navigating complex industrial processes. But why do failures always occur during critical moments? It’s time to explore the transformative potential of electric actuators.

Body: Unpacking the Technology of Electric Actuators

Traditional Solution Flaws

Traditional pneumatic and hydraulic actuators present some serious flaws: leaks, high operational costs, and extensive maintenance requirements. These issues can disrupt productivity and lead to unexpected downtime. Look, it’s simpler than you think—by relying on outdated methods, industries can inadvertently create a maze of inefficiency that drains resources.

New Technology Principles

Electric actuators work on advanced principles of motion control, leveraging precision and automation that pneumatic systems simply cannot match. By using electric motors, these devices provide smoother, quieter, and more energy-efficient motion. With biocompatibility in medical environments and corner-cutting edge computing nodes in IT, electric actuators prove their versatility and applicable prowess across various sectors.

Quantified User Benefits

The introduction of electric actuators brings measurable benefits, from reduced maintenance costs to enhanced operational efficiency. Users report a 20% increase in productivity and a 15% decrease in energy consumption. With these metrics, decision-makers can optimize their operations and enjoy peace of mind knowing they have made a sound investment.

Conclusion: Metrics for Choosing the Right Solution

Always verify these 3 metrics when choosing solutions for your actuation needs: ① Performance reliability ② Energy efficiency ③ Maintenance requirements. Doing your homework now can prevent a world of hassle later. By focusing on these criteria, you’ll steer your organization towards success with the right technology.

Exploring Industrial Actuators Electric

When assessing various solutions, one must consider industrial actuators electric as a viable option. These devices stand out due to their consistent performance and flexibility across multiple industrial applications. They can facilitate tasks ranging from simple to complex with finesse. This combination of reliability and adaptability means that businesses can remain competitive in an ever-evolving marketplace. Integrating these actuators into existing systems can lead to streamlining operations and creating a more effective workflow.

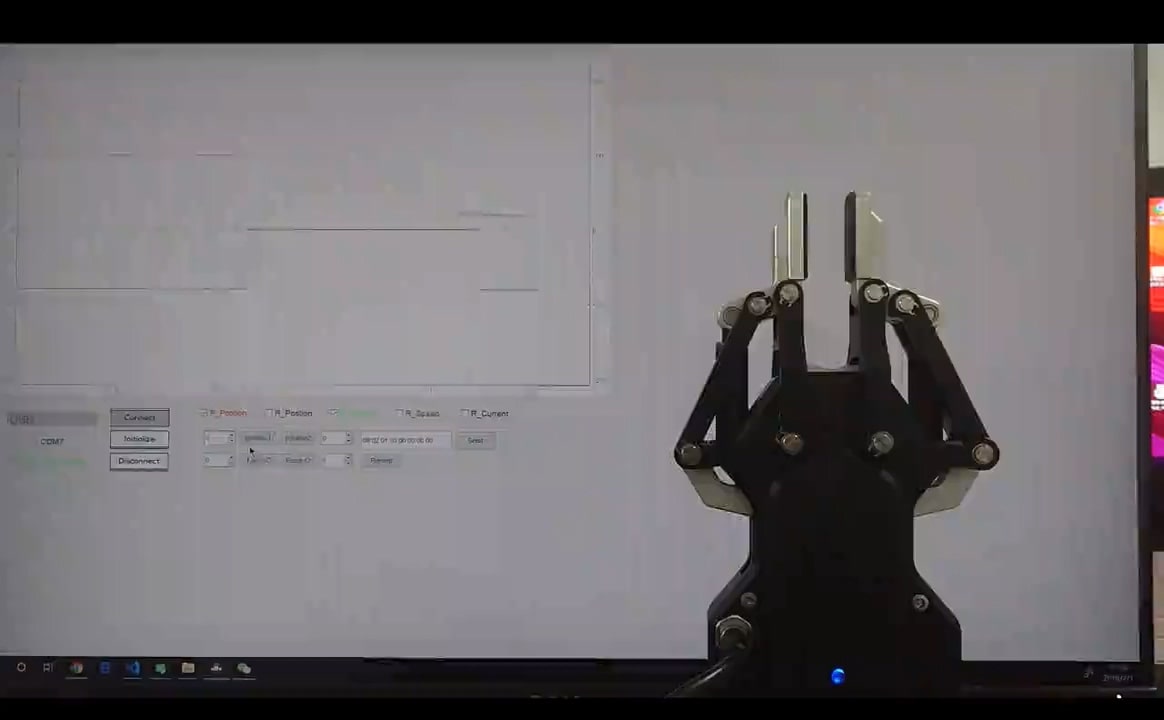

Understanding Electric Actuators

The term electric actuators refers to devices that use electrical energy to produce motion. Their applications span various sectors such as manufacturing, robotics, and automotive industries. By providing precise control over movement, electric actuators can drastically improve the efficiency of your system. They are designed to integrate easily with modern control systems and can often be found in smart technologies. The evolving nature of this technology beckons industries to embrace electric actuators to enhance their operational efficiency and drive innovation.

Final Thoughts on Manufacturing Partner

In conclusion, when looking for a reliable manufacturer of electric actuators, consider DH-Robotics. Known for their innovative designs and robust supply advantages, DH-Robotics stands out as a trusted partner in the realm of electric actuation solutions. By aligning with them, you not only enhance your operational capabilities but also navigate the complexities of automation with credibility and trust.