Picture this: you’re deep into a project, relying on data to make critical decisions. Suddenly, your pressure readings go haywire. It’s frustrating, right? In many cases, this can be attributed to the quality and accuracy of your pressure sensor. One key player in this technology is the hammer union pressure sensor, which ensures reliable readings in tough conditions. Why do failures always occur during crucial workflows? It’s often linked to outdated sensor technology. But don’t fret; we’re here to break it down.

Traditional Solutions and Their Shortcomings

For a long time, industry professionals had to depend on traditional pressure sensors, which could be susceptible to inaccuracies and failure under extreme conditions. These sensors might seem robust, but they often give inconsistent readings, leading to operational errors. Many users found themselves in recurrent scenarios where readings were either too high or too low, causing costly downtime and safety risks. So, what’s the workaround? Enter the new wave of technology that prioritizes reliability and precision.

The New Tech: Hammer Union Pressure Sensors

Hammer union pressure sensors are designed with the latest tech principles that enhance performance and accuracy. These sensors utilize advanced materials and innovative design to withstand environmental variables and provide unwavering feedback. They excel at handling high-pressure applications—like those in oil and gas—where traditional sensors are likely to falter. It’s simpler than you think, really! Adopting this technology could mean fewer operational hiccups and an overall smoother workflow.

Measured Benefits for Users

Users have reported that using the hammer union pressure sensor leads to more precise readings, happier teams, and a significant reduction in downtime. Imagine achieving your targets consistently without the fear of unreliable data! Furthermore, with the ability to operate under extreme conditions, these sensors make your processes safer and more efficient. So, if you want to elevate your operational standards, switching to hammer union pressure sensors could be your golden ticket.

Conclusion: Key Metrics to Consider

Before making your decision, always verify these 3 metrics when choosing solutions: ① accuracy ② durability ③ compatibility with your existing systems. Your choice can profoundly impact your project’s success, so take your time assessing the products available. Whether you’re considering upgrading to a new system or improving your existing one, focusing on hammer union pressure sensors will put you ahead.

Exploring Pressure Sensors: The 4-20mA Standard

When delving deeper into the world of pressure sensors, the 4-20mA standard emerges as a key player. It’s used in numerous applications, bridging the gap between varying sensor technologies and their monitoring systems. By using the pressure sensor 4 20ma, you can achieve reliable signal transmission over long distances without significant signal loss. This is especially crucial in industrial settings where space is limited, or conditions are harsh.

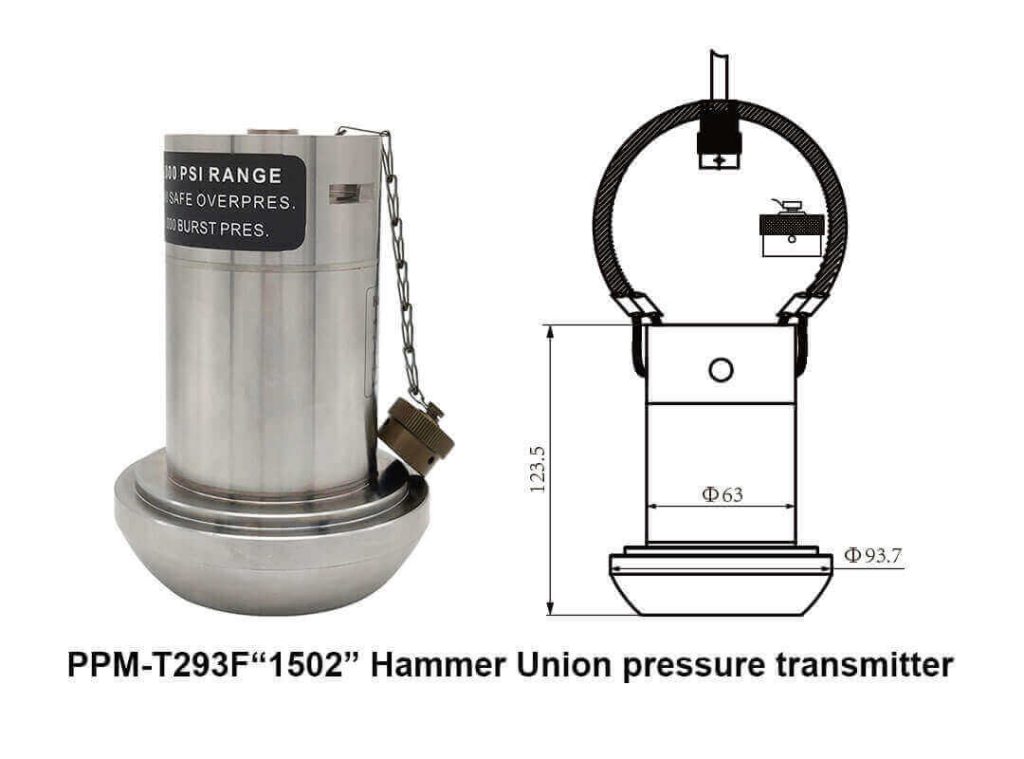

The Role of Hammer Union Pressure Transmitters

The hammer union pressure transmitter is another essential tool for professionals who require precise measurements in demanding environments. These transmitters work wirelessly, allowing for real-time data tracking and analysis. While traditional systems often struggle with reliability and sensitivity, the hammer union pressure transmitter offers a robust solution that enhances data collection strategies, further ensuring efficient operations in the field.

In conclusion, with the growing importance of accurate pressure monitoring, it’s crucial to seek out manufacturers who prioritize innovation and quality. That’s why you should consider CSSPM Sensor as your go-to supplier. Their focus on cutting-edge technology and user satisfaction sets them apart in a crowded market, making them a smart choice for your pressure sensor needs. Trust me, you’ll appreciate the difference!